Computer Vision Processing

Ensuring quality with technology…

Pizza Quality Control system was developed with AI solutions in the concept of industry 4.0. The system includes Computer Vision, Image Classification and Object Recognition, developed by using Conventional Neural Network models with the latest improvements in the field of AI such as Mask-RCNN, YOLO and DETECTRON. The development of Computer Vision Algorithms is for the detailed inspection of a pizza’s size, crust, and ingredient distribution for optimal production. This results in significant time, effort and materials savings.

Quality Control System

As general practice, manufactured goods go through a quality check process prior to shipment to customers. This check is usually done by humans, leading to errors and mishaps. Computer Vision Quality Control Systems aim to eliminate these errors by utilizing cameras and advanced image processing algorithms to identify manufacturing defects thus stopping shipments. Defect detection can vary; however, the most common ones are artwork discrepancies, missing unit, or physical defect on the item. Quality control is completed in under 2 seconds through advanced machine learning algorithms.

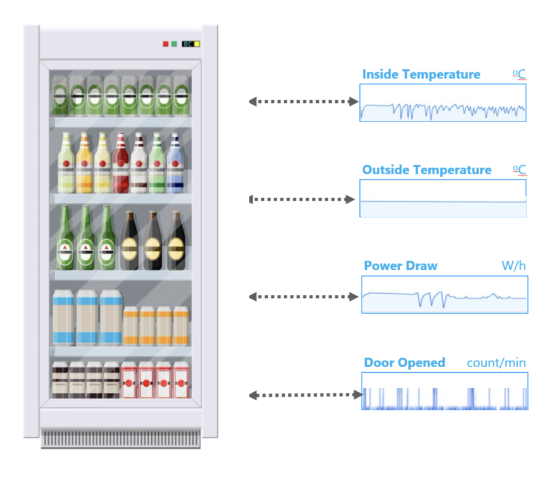

With the computer-aided visual recognition system that we developed, we can determine whether any product other than the products of the relevant brand is placed in beverage cabinets in places such as markets, restaurants and bars. We placed accelerometers onto each shelf to measure the required occupancy predetermined by the company standards.

In addition, we can instantly monitor the temperature of the cabinet with the heat meters we use in the cabinet and send warnings, if it remains below or above what it should be. With our X and Y axis positioning technology, we can instantly recognize if there is a location change of the cabinet.

Remote Monitoring

Smart Fridges have multiple sensors that log data to their internal database.

This data can be retrieved to evaluate the health safety and operating conditions of each fridge to maximize consumer satisfaction and reduce operational costs.

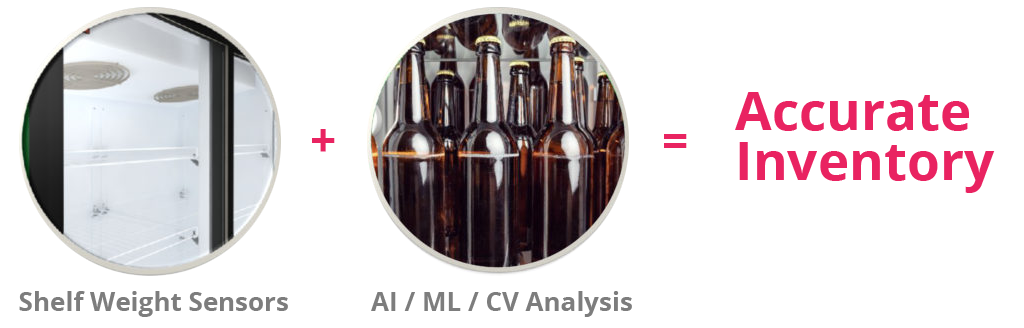

Inventory In Realtime

SKUs in the Smart Fridge are determined by the AI/ML/CV module. Weight of each SKU is defined in master database

Shelf weights are constantly monitored

Inventory is calculated based on the defined planogram, weight of each shelf and Computer Vision feedback from the Smart Fridge

Map Display GPS Positioning

Report operational Smart Fridge inventory

Display real time status of each Smart Fridge Visually represent each Smart Fridge location on a digital map