Oil & Gas

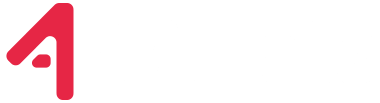

PYM Human Resource

Measurement System

A web-based calculation and reporting tool designed to ensure that all projects to be carried out within the refinery are followed under four main disciplines, the calculation of approximate human effort, the follow-up and deviations of the effort made with the calculated effort, and the reporting of all projects in a consolidated manner.

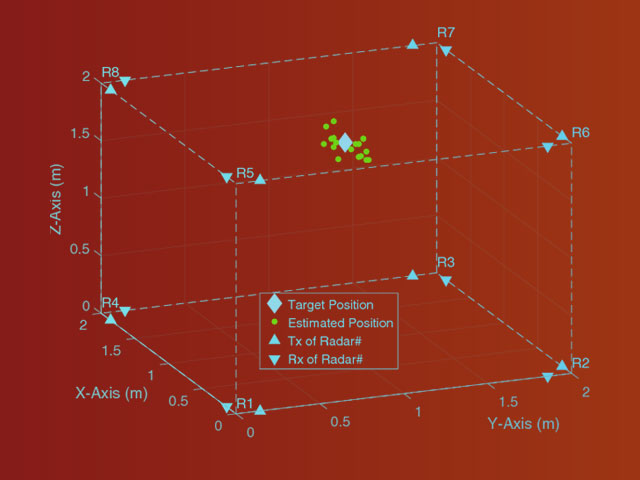

3D Positioning System

Refineries are considered among the most dangerous working places in the world. With the 3D Positioning System, the location of the field personnel in the refinery is determined in real time and displayed on an interactive map. In addition to the position information, the person's pulse information, height from the ground, whether or not he falls, and the measurement of harmful gas in the environment can be transmitted to the central processing units in real time. In case of emergency, the polling count in emergency gathering areas can be performed automatically through the system. The system can work with all Android supported smart watches and wearable technologies. Monitoring interfaces consist of Web and Mobile based applications.

Field Measurement IoT

During maintenance times, the data from the refinery sensors must be recorded on the maintenance forms and recorded in the ERP / MRP system. Field Measurement IoT system has been developed in order to facilitate this process, reduce paper usage and transfer data to related systems without any errors. Integration with SAP has been realized in order to automatically display maintenance orders and direct relevant refinery personnel to the sensor. The system can work on Android-based tablets both online and offline.

Corrosion

Prediction System

A mathematical sampling platform where internal corrosion of pipelines is estimated and reported. It tries to estimate the internal corrosion of the pipeline according to the content passing through the pipeline, the length of the pipeline, the pH level of the content, the number of elbows of 90 degrees, above and below the pipeline, and the condition of about 20 parameters. Pipe segments that appear risky as a result of the estimation process are marked on the 3D model. The system, which operates according to hydrodynamic and thermodynamic models, benefits from intensive machine learning. All the parameters used during the calculation can be taken from Scada or OSI.